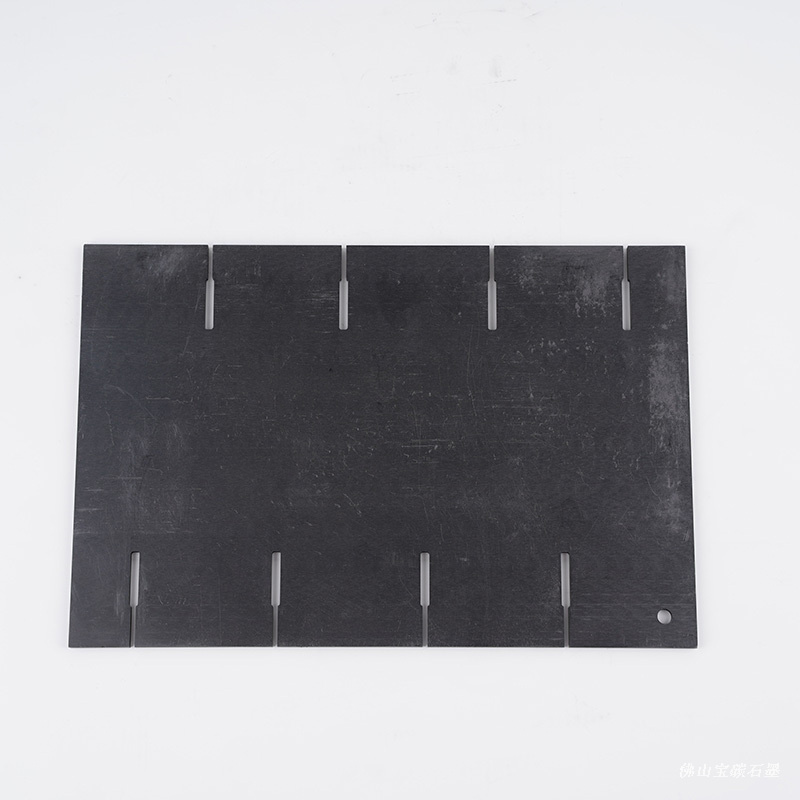

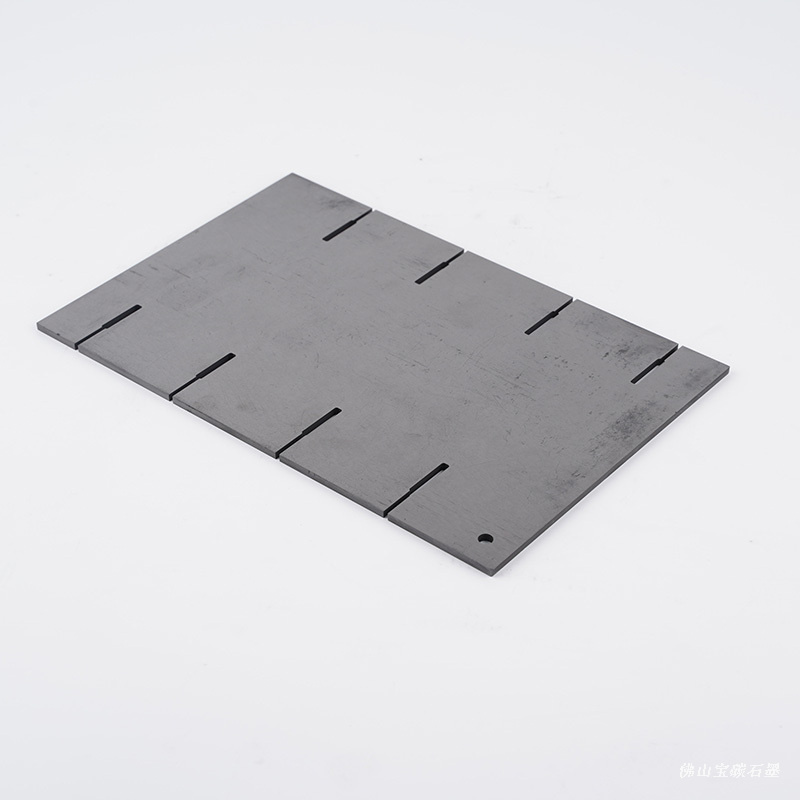

The use of graphite anode plate is in the electrolytic cell. The graphite anode plate is the stage where the current flows into the electrolyte. In the electrolysis industry, the anode is generally made into a plate shape, so it is called a graphite anode plate.

The Koboi Graphite Anode Plate is a high-performance component designed for various industrial applications, particularly in electrochemistry, metallurgy, and energy storage. Crafted with precision and utilizing advanced materials and manufacturing techniques, this product exemplifies Koboi's commitment to excellence in providing solutions for diverse industries.

Key Features

High-Quality Graphite: Koboi sources the finest quality graphite materials to ensure superior performance and longevity. The graphite used in these anode plates is chosen for its excellent electrical conductivity, thermal stability, and resistance to chemical corrosion. It undergoes rigorous testing and quality control measures to guarantee consistency and reliability.

Optimized Design: The anode plate boasts an optimized design that enhances its efficiency and effectiveness in various applications. Its precise dimensions and geometric structure facilitate consistent and reliable performance. Additionally, the design may incorporate features such as enhanced surface area or channels for improved electrolyte flow, further optimizing performance.

Corrosion Resistance: Koboi's graphite anode plate is highly resistant to chemical corrosion, making it suitable for use in aggressive environments such as electrochemical cells and electrolytic processes. The material composition and surface treatment techniques ensure long-term stability and protection against corrosive agents present in the electrolyte.

Excellent Conductivity: The exceptional electrical conductivity of the graphite material ensures minimal energy loss during electrochemical reactions, making it ideal for applications that require high current densities. The low resistivity of graphite allows for efficient electron transfer, optimizing energy conversion and process efficiency.

Thermal Stability: This anode plate can withstand elevated temperatures, making it suitable for applications involving high-temperature electrolysis and other thermal processes. The material's thermal conductivity helps dissipate heat evenly, preventing hot spots and ensuring consistent performance even under demanding operating conditions.

Durable and Long-Lasting: Koboi's dedication to quality ensures that these anode plates have a long service life, reducing the need for frequent replacements and maintenance. The robust construction and resilience to mechanical stress ensure durability, making it a cost-effective solution for industrial applications requiring reliable performance over extended periods.

Customizable: Koboi understands that different industries have unique requirements. As such, these graphite anode plates can be customized to meet specific dimensional and performance criteria, ensuring they fit seamlessly into your application. Customization options may include tailored surface coatings, electrode configurations, or dimensional adjustments to suit specific operating conditions and integration needs.

Applications of Graphite Anode Plate

The Koboi Graphite Anode Plate finds applications across a wide spectrum of industries, including:

Electrochemical Cells: Used as a key component in various electrochemical cells, such as fuel cells, electrolyzers, and electroplating cells. The high conductivity and corrosion resistance of graphite make it ideal for facilitating efficient chemical reactions and electron transfer processes.

Metallurgy: Ideal for processes like aluminum smelting and refining, where a robust and corrosion-resistant anode is required. The graphite anode plate withstands harsh operating conditions and maintains stability during prolonged exposure to molten metals and corrosive electrolytes.

Energy Storage: Can be employed in energy storage systems, including flow batteries, to facilitate efficient energy conversion and storage. Graphite's conductivity and durability contribute to the performance and reliability of energy storage solutions, enabling sustainable power generation and grid stabilization.

Chemical Industry: Suitable for chemical processes that demand a reliable and chemically inert anode material. The corrosion-resistant properties of graphite ensure compatibility with a wide range of chemical substances, making it suitable for applications such as electrolytic production of chlorine, hydrogen, and other industrial chemicals.

Water Treatment: Utilized in electrochemical water treatment systems for efficient removal of pollutants and contaminants. The graphite anode plate facilitates electrocoagulation, electrooxidation, and other electrochemical processes used in wastewater treatment, ensuring effective pollutant removal and water purification.

Why Choose Koboi?

Koboi has established itself as a trusted name in the field of advanced materials and industrial solutions. With a focus on quality, innovation, and customer satisfaction, Koboi consistently delivers products that exceed industry standards. The Koboi graphite anode plates for efficient electrolysis are no exception, offering reliability, performance, and versatility to meet the evolving needs of modern industries.

Invest in Koboi's Graphite Anode Plate to experience the difference that quality and precision engineering can make in your industrial processes. Whether you're working on research projects, industrial-scale production, or environmental solutions, Koboi's graphite anode plate is your dependable partner for success.

_853.jpg)

_867.jpg)