Graphite is a versatile carbon allotrope that exists in various forms, each with unique properties and applications. The main types of graphite products are natural graphite, which includes flake, amorphous, and vein graphite, and synthetic graphite. Here's a closer look at these different types of graphite products:

Flake Graphite

Flake graphite occurs as flat, plate-like particles with hexagonal or angular edges, distributed throughout metamorphic rocks such as limestone, gneiss, and schist. It comes in four basic sizes: jumbo, large, medium, and fine. Flake graphite is highly sought after due to its applications in the auto industry, particularly in the anodes of lithium-ion batteries used in electric vehicles.

Amorphous Graphite

Amorphous graphite is a microcrystalline form of natural graphite, typically darker and less reflective than other varieties. It is formed by the metamorphism of coal beds or carbon-rich sediments and has a lower graphitic carbon level compared to other natural crystalline graphite types. Amorphous graphite is often used in foundries, refractories, steel production, brake linings, and pencils.

Vein Graphite

Also known as lump graphite, vein graphite is found in fissures or fractures and appears as massive platy intergrowths of fibrous or needle-like crystalline aggregates. It is believed to have hydrothermal origins and is considered the rarest form of natural graphite. Vein graphite is used in advanced, thermal, and high-friction applications such as car brakes and clutches, and can also be used in applications requiring high thermal and electrical conductivity.

Synthetic Graphite

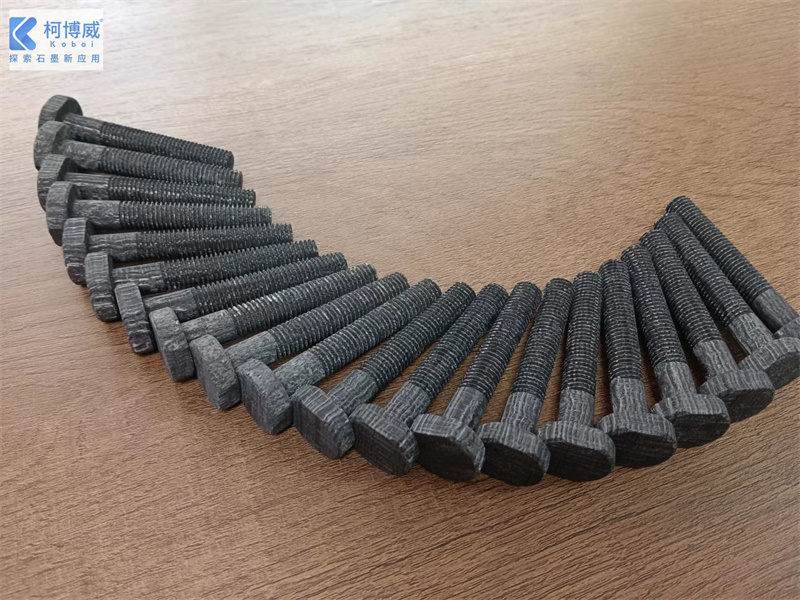

Synthetic graphite is produced industrially from petroleum coke as a raw material. It is obtained by graphitizing non-graphitic carbon through various processes, such as chemical vapor deposition, decomposition of thermally unstable carbides, or crystallization from metal melts supersaturated with carbon. Synthetic graphite is used to create moldings like electrodes, cylinders, and blocks.

Graphite Grades and Properties

Graphite comes in various grades, each with specific properties that make them suitable for different manufacturing applications. Some common graphite grades include:

● UHP (Ultra-High Power) and HP (High Power) graphite electrodes for electric arc furnaces

● High-quality brushes made from customized grades for aerospace, automotive, construction, mining, and other industries

● Proprietary grades for rotors & vanes used in aerospace, chemical, environmental, food & beverage, medical, plastics, and printing & paper industries

● Carbon graphite, electrographite, resin-bonded graphite, and metal graphite blank stock for machining end products

The properties of graphite, such as high thermal and electrical conductivity, low friction, self-lubrication, and resistance to extreme conditions, make it a versatile material for various manufacturing applications.

Graphite Applications in Manufacturing

Graphite products find applications in numerous manufacturing industries, including:

● Steel, aluminum, chemical, silica, silicon carbide, silicon nitride, heat treating, diamond tooling, and automotive industries

● Aerospace, construction, mining, power generation, printing & paper, renewable energy, and transportation

● Agriculture, environmental, oil & gas, and pharmaceuticals

● Some specific applications include electric arc furnaces, dryer bearings, electrical contacts, mechanical seals, hot glass handling, turbine & compressor rings, wear plates, and screening equipment.

Customized Graphite Solutions for Your Business

At Koboi Graphite, we understand that every business has unique requirements when it comes to graphite products. Our professional team works closely with clients to develop customized solutions that meet their specific needs, ensuring optimal performance and cost-effectiveness.

Whether you require flake, amorphous, vein, or synthetic graphite, Koboi Graphite has the expertise and resources to deliver the right product for your manufacturing process. Contact us today to discuss how we can help you enhance your operations with our high-quality graphite products.

_853.jpg)

_867.jpg)